Circuit boards engineered with Design for Excellence

Successful products require circuit boards engineered with Design for Excellence

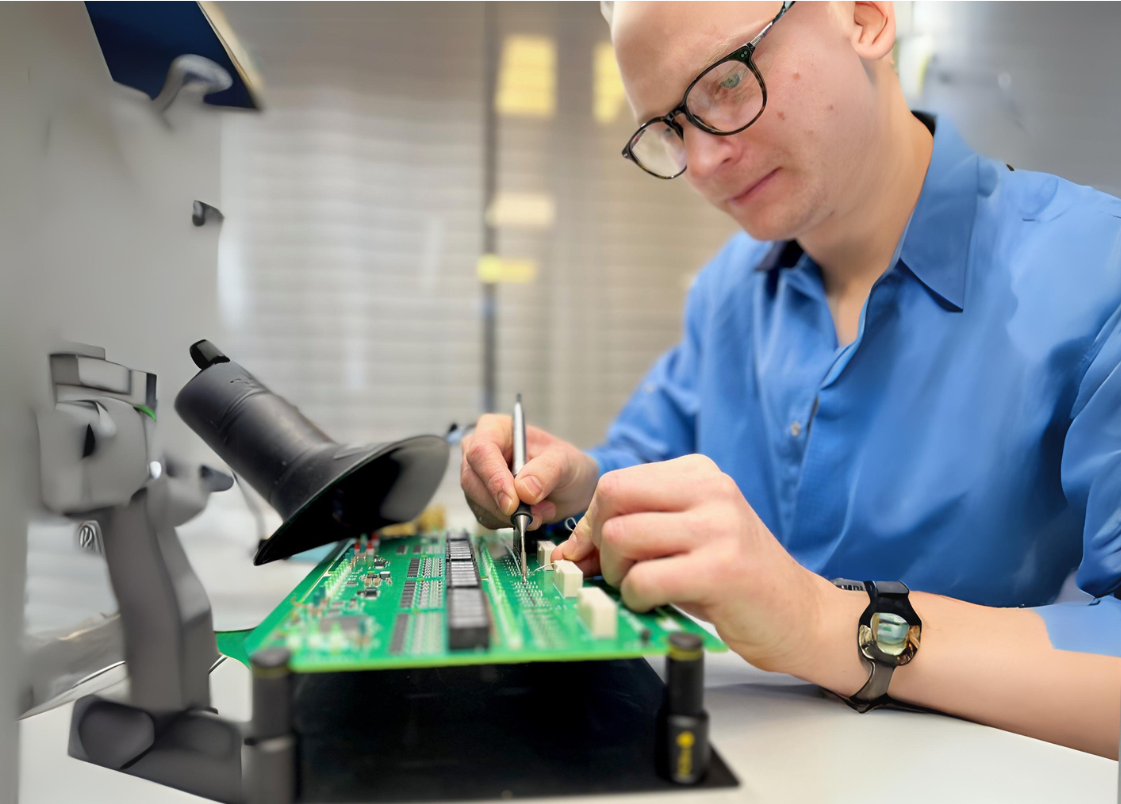

In Together Tech's office, there are many electronics engineers who are extra passionate about the heart of many products and systems: the circuit board, also called Printed Board Assembly (PBA).

With curiosity and passion, they take on demanding design assignments for our customers in various industries who integrate advanced electronics into their products. Our customers know how important excellence in circuit board construction is for the final result to be innovative, reliable and future-proof products and systems.

They demand Design for Excellence throughout the value chain. From the idea stage to design, component selection, manufacturing, testing and verification in electronics labs.

We have been part of the electronics industry's long journey of change

About twenty years ago, the electronics industry looked different compared to today. Back then, it was common for product-owning companies to have their own internal development departments. Gradually it has changed. Companies that are about to launch a new product increasingly purchase the development and manufacture of circuit boards and printed circuit boards from external partners.

Together Tech has been a complete partner to the industry during the more than twenty-year change journey. Our electronics engineers have helped many companies quickly reach the market with new products and systems. Their competence and experience in circuit board construction lays the foundation for reliable products with high quality, lower production costs, faster "time to market" and a positive ROI - Return On Investment. Product development costs money and it is an investment that should pay off as soon as possible.

Electronics engineers with holistic thinking are needed

Good electronics are not developed overnight. A poorly designed circuit board can result in unnecessary development costs, delayed market launches and quality defects that lead to a product not being a market success. To drive and run electronics projects where circuit board construction is included as an important step is today considered as a main challenge for Swedish industry.

A strategic innovation program funded by the Swedish state resulted a few years ago in the publication of the "Smartare Elektronikhandboken". It is a handbook that gives good advice but also emphasizes how important the interface is between the development of electronics and the manufacture of a product.

The book describes it as reliability and manufacturability must be built into a product. It requires a holistic approach to circuit board construction, and for Together Tech's electronics engineers it is obvious to work with a broad overall perspective.

- A common strength of our electronics engineers is holistic thinking. A small detail that is overlooked during the construction work can negatively affect the final product if one does not work with a broad perspective. It's about minimizing risks and doing it right from the start. Our engineers understand the interaction between electronics, software and mechanics. They often work closely in development teams with colleagues from different technical areas. Together, they create good processes that produce end products with high quality, says Mikael Duvander.

Large lab and test capacity after greatly expanded in-house resources

Together Tech is in an exciting and intensive development phase where investments are being made in the remodeling and expansion of premises at several of our offices, and in smart tools for circuit board construction. The expanded in-house resources create space for many more demanding electronics projects. Projects where simulations of functions are often required before component selection, and tests and verifications in electronics labs. EMC measurements to verify that the requirements of standards and EMC directives are met are often included as an important part during the construction phase of many projects. The investment in expanded in-house capacity includes reinforced lab resources as an important part.

- We can perform many of the requirements for verifying that a construction's requirement specification is met in our own laboratories. It provides the opportunity for modifications and improvements to a product, which reduces the risk of project delays and increased costs that can arise if you realize at a late stage that important requirements are not being met. We also have well-established collaborations with external labs when it comes to EMC measurements, explains Mikael.

We are happy to take on the role of Product Responsible

Technological development is accelerating and many companies are streamlining operations and focusing resources on, for example, sales and customer service. They are looking for partners who can drive product development, and Together Tech has the resources to take on such overall responsibility.

- For Västtrafik, for example, we have developed a new electrical switchboard that has now been installed in some 4,000 buses for public transport. Västtrafik wanted a convenient solution where you can concentrate on running good public transport instead of administrating orders and deliveries. We handle all of that and we can do the same for other companies that want to focus on sales and market development and not on product management, says Mikael Duvander.

Contact

Related content