Mechanical Engineering

Tomorrow's knowledge for the products of the future

The world is changing, and so is mechanical engineering

We see this in the abundance of new materials and production methods we use in our assignments. The positive thing about the development is that you now have the opportunity to produce previously complicated products faster and more cost-effectively.

Regardless of the industry you operate in, mechanical and material development means new important opportunities that result in better end products. We tackle this with great curiosity and creativity, and together with you we transform the development into the products of the future!

Overall responsibility – Product development from start to finish

We are experts in all stages of product development, from research and concepts to finished products. Good cooperation with your customers and subcontractors is the key to successful projects. We have extensive experience of the entire process, from ideas to the development of prototypes to serial production.

We offer

- Concept development

- Ergonomics, usability

- Prototyping

- Construction

- Drawings, setting requirements

Product development – combined expertise

When you hire us, you get access to broad and deep knowledge in industrial design, mechanics, electronics, software, usability and production. With our combined expertise, we develop products that meet your specifications and the standards within your industry.

Test and verification – the common thread throughout the project

In our development projects, we start the analysis and make preparations for how a product should be tested at an early stage. This is to ensure that the requirements can be tested and that they are met. We can define the need for test equipment early on, this gives you as a customer security and predictability in the project.

Simulations and analysis – strength and flow

How do we ensure that your product works and acts as intended BEFORE it goes into production? FEM, CFD and Moldflow simulations enable us to shorten and ensure development work early in the process. The analyses result in more secure strength, better flow, reduced risks, lower costs and fewer changes at a late stage.

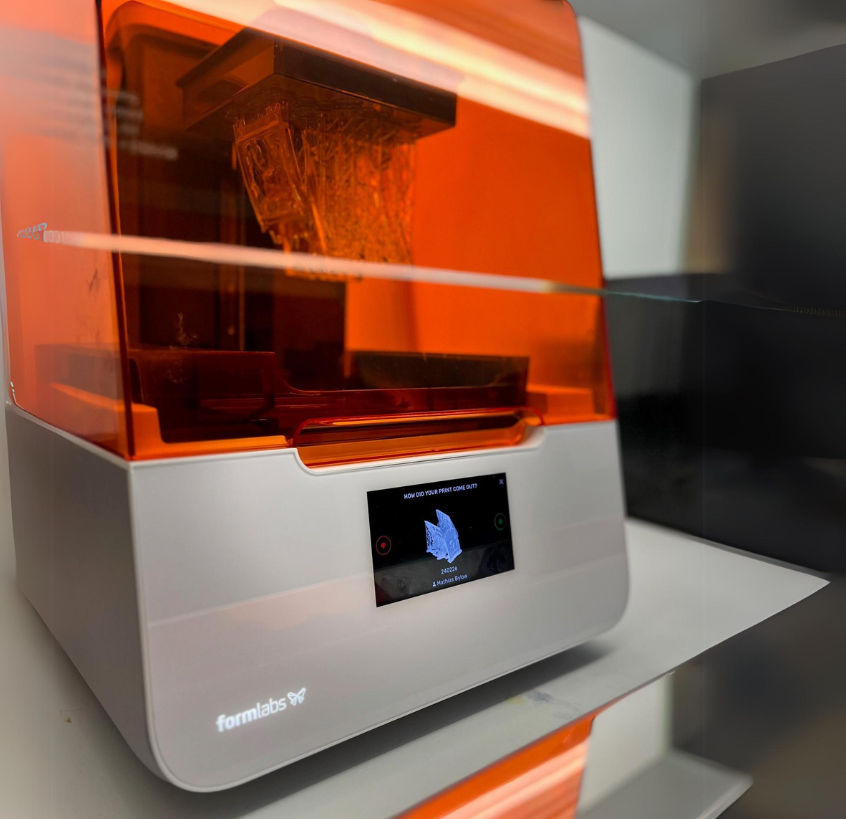

Rapid prototyping

3D printed or machined? Rapid prototypes or those that can handle high demands, must there be conflicting demands? Extensive experience and knowledge, a large network of suppliers and our own machinery mean that we deliver the right quality of the prototypes to our customers on a daily basis.

Together, we guide you through the jungle of constantly changing methods and materials. One example is additive prototyping in our prototype and test center. We have experienced engineers who are trained prototype technicians and work in our lab with 3D printers. The technology makes it possible to produce prototypes in a few hours compared to perhaps a week with external suppliers.

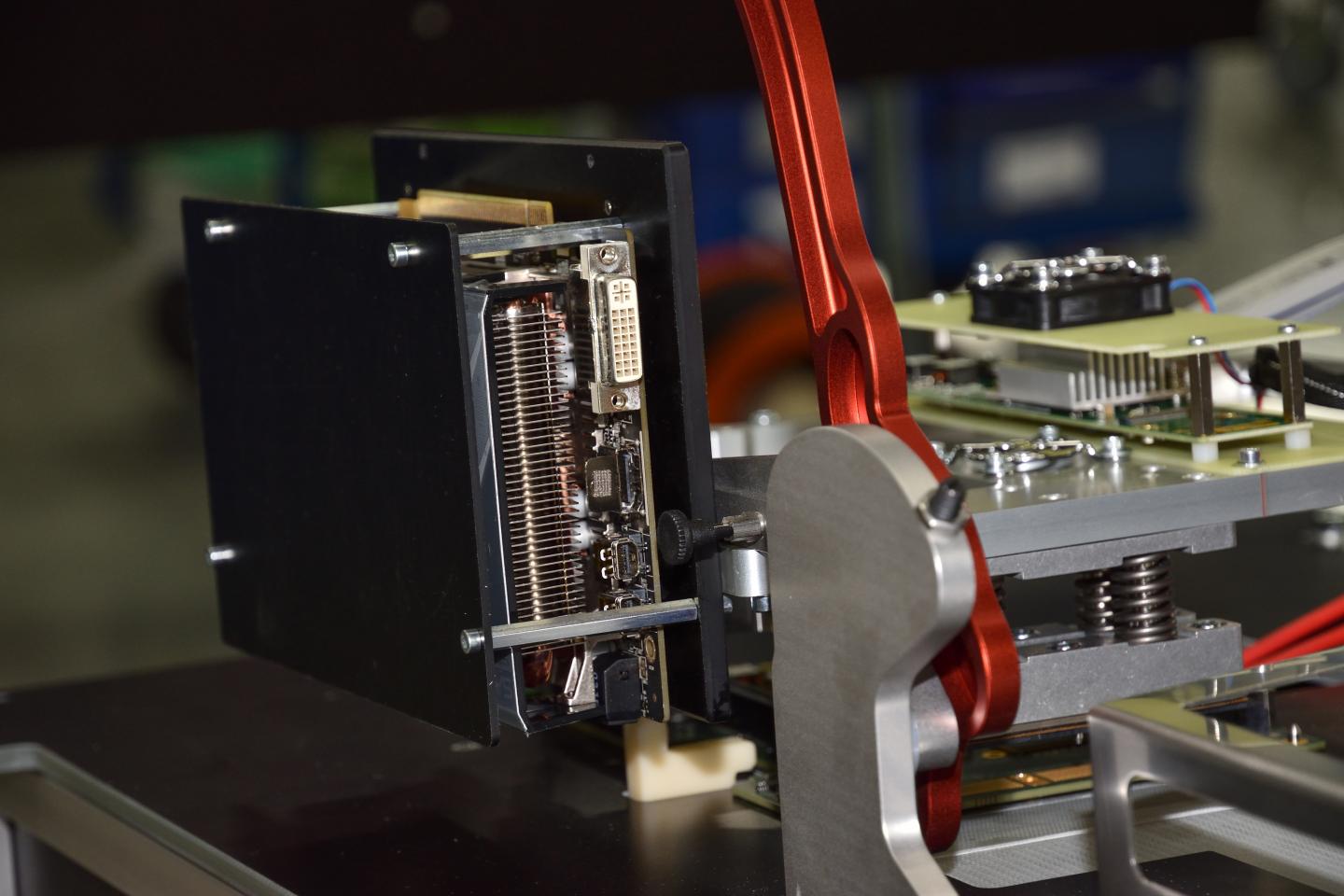

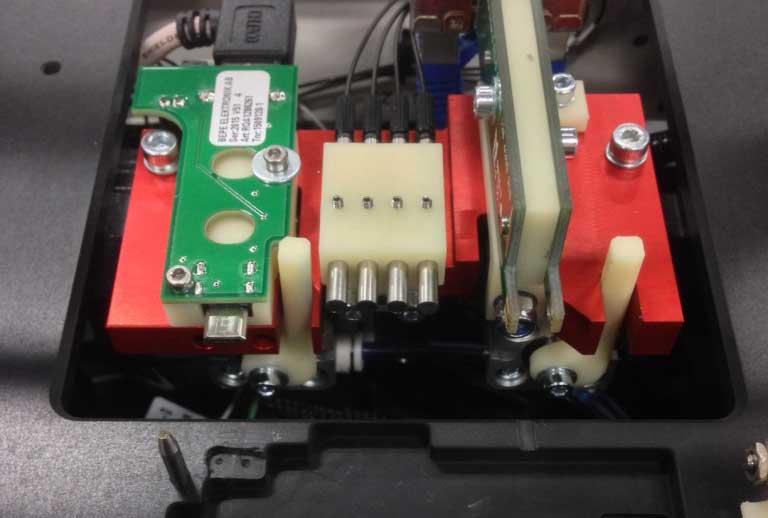

Fixtures - quality assurance in a precise place

We develop and manufacture both test fixtures and assembly fixtures that are customized.

Usability – design for ease of use!

Creating user-friendliness - or usability - is about putting oneself in the user's situation. Through careful research, user studies and tests, we identify the needs and behaviors of your target groups, and then let our UX designers optimize the flow and user experience based on the users' needs. The work includes the product's physical design and its interaction with displays and interfaces.

Do you want to know more? Contact us

Related content